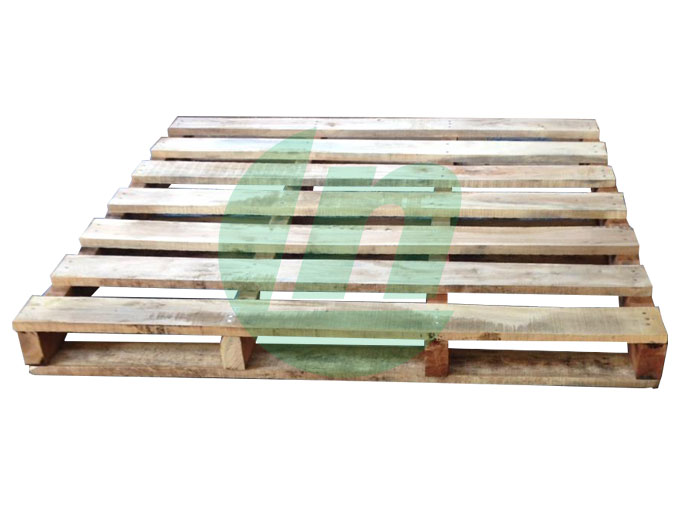

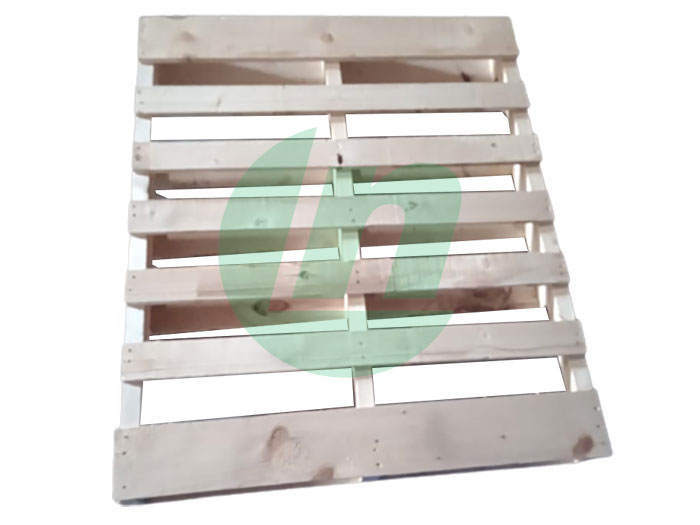

Two-way pallets are produced with 3 fundamental parts for example lower deck board, top deck board, and side conveyor. They are alluded to as “two-way” since it’s an option exclusively for forklift trucks to enter them from the front or back. Two-way pallets are of the very top notch as whatever other bed that we produce and are likewise the least expensive. In any case, mobility is restricted in light of the fact that the forklift just has two places of section. In the event that utilizing space in a distribution center is of ideal concern or the beds will be stacked as cargo, the better decision would be four-way beds.

Two-way pallets are by and large indented through the stringers to make it a four-way bed. These sorts of beds are principally used to stick to the principles of GMA (Grocery Manufacturer’s Association), a standard which is broadly acknowledged in the USA. These are less work serious to produce and are commonly both more grounded and more savvy than four-way pallets however offer less adaptability concerning taking care of thus stockpiling, space use and transport/delivering expenses can be compromised. These beds are additionally accessible with essential intensity therapy or fumigation according to the ISPM15 standards.